Umgaqo wokukhetha izixhobo

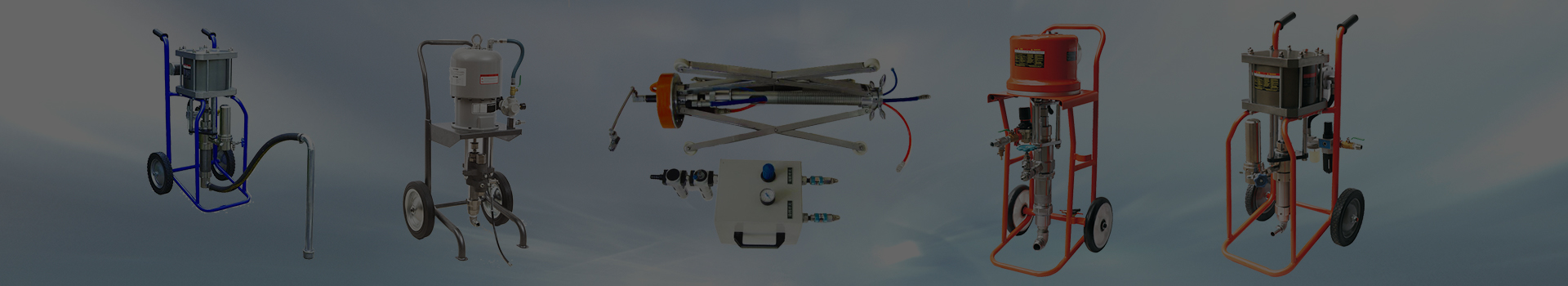

Zininzi iintlobo zezixhobo zokutshiza ezingenamoya, eziya kuthi zikhethwe ngokwale miba mithathu ilandelayo.

(1) Ukukhethwa ngokweempawu zokugquma: okokuqala, qwalasela i-viscosity ye-coating, kwaye ukhethe izixhobo ezinomlinganiselo woxinzelelo oluphezulu okanye inkqubo yokufudumeza i-coatings kunye ne-viscosity ephezulu kunye ne-atomization enzima.Izixhobo ezikhethekileyo ezinomzekelo okhethekileyo ziya kunyulwa kwi-coating-component-component, i-coating-based-coating, i-zinc rich coating kunye nezinye iingubo ezikhethekileyo.

(2) Khetha ngokwemeko ye-workpiece edibeneyo kunye nebhetshi yokuvelisa: le yeyona nto iphambili yokukhetha izixhobo.Kwibhetshi encinci okanye encinci yezinto zokusebenza ezigqunyiweyo, khetha ngokubanzi imodeli ngexabiso elincinci lokutshiza ipeyinti.Kwibhetshi enkulu kunye nenkulu yezinto zokusebenza, ezinjengeenqanawa, iibhulorho, iimoto, imigca ezenzekelayo eqhubekayo yokupeyinta, khetha imodeli enexabiso elikhulu lokutshiza ipeyinti.Ngokuqhelekileyo, umthamo wokutshiza ipeyinti <2L / min incinci, i-2L / min - 10L / min iphakathi, kwaye> 10L / min inkulu.

(3)Ngokomthombo wamandla okhoyo, isixhobo sokutshiza esingenamoya esingenamoya sinokukhethwa kuba kukho imithombo yomoya ecinezelweyo kwiindawo zokusebenza zokutshiza ngokubanzi.Ukuba akukho mthombo womoya ucinezelweyo kodwa unikezelo lwamandla kuphela, izixhobo zokutshiza ezingenamoya zombane ziyakunyulwa.Ukuba akukho mthombo womoya okanye unikezelo lwamandla, izixhobo zokutshiza ezingenamoya eziqhutywa yi-injini zingakhethwa

Izinto eziluncedo kumatshini wokutshiza ongenamoya woxinzelelo oluphezulu:

1. Ukusebenza kakuhle kokutshiza.Isitshizi sitshiza ipeyinti ngokupheleleyo.Ukuhamba kokutshiza kukhulu, kwaye ukusebenza kakuhle kokwakhiwa kumalunga namaxesha ama-3 kunomoya.Umpu ngamnye unokutshiza i-3.5 ~ 5.5 ㎡/min.Umatshini wokutshiza ongenamoya woxinzelelo oluphezulu unokusebenzisa imipu ye-12 yokutshiza ngaxeshanye.Ubukhulu bombhobho wedayamitha inokufikelela kwi-2mm, efanelekile kwiingubo ezahlukeneyo zokuncamathelisa.

2. Ipeyinti ephinda kabini.Ipeyinti etshizwe ngumatshini wokutshiza umoya iqulethe umoya oxinanisiweyo, ngoko iya kuphinda ibuyele xa ichukumisa umphezulu wento eza kugqunywa, kwaye inkungu yepeyinti iya kubhabha imke.Inkungu yepeyinti etshizwe ngoxinzelelo oluphezulu lokutshiza okungenamoya ayinanto iphinda ibuyele ngenxa yokuba akukho moya ucinezelweyo, onciphisa iinwele zokutshiza ezibangelwa yinkungu yepeyinti ebhabhayo, kwaye iphucula izinga lokusetyenziswa kwepeyinti kunye nomgangatho wefilimu yepeyinti.

3. Inokutshizwa ngepeyinti ephezulu kunye nephantsi ye-viscosity.Njengoko ukuthuthwa kunye nokutshiza kweengubo kuqhutyelwa phantsi koxinzelelo oluphezulu, iingubo eziphezulu ze-viscosity zinokutshizwa.Umatshini wokutshiza ongenamoya onoxinzelelo oluphezulu unokude usetyenziswe ukutshiza iingubo eziguquguqukayo okanye iingubo ezinemicu.I-viscosity yokugquma yomshini wokutshiza ongenamoya woxinzelelo oluphezulu ingaba phezulu njenge-80 s.Ngenxa yokuba i-coating ene-viscosity ephezulu inokutshizwa kwaye umxholo oqinileyo wokugquma uphezulu, i-coating etshizwe ngaxeshanye inzima, ngoko ke amaxesha okutshiza angancitshiswa.

4. I-workpiece enemilo enzima inokuguquguquka okulungileyo.Ngenxa yoxinzelelo oluphezulu lomatshini wokugquma ongenamoya woxinzelelo oluphezulu, unokungena kwimingxuma emincinci kumphezulu wesixhobo sokusebenza esinzima kakhulu.Ukongezelela, ipeyinti ayiyi kuxutywa ngeoli, amanzi, amaphephancwadi, njl. emoyeni oxinyiweyo ngexesha lokutshiza, ukuphelisa iziphene zefilimu yepeyinti ezibangelwa ngamanzi, ioli, uthuli, njl. emoyeni oxinyiweyo, ukwenzela ukuba ipeyinti elungileyo. ifilimu inokwakheka nakwizikhewu kunye neekona.

Izinto ezingeloncedo:

Ubukhulu bamathontsi enkungu yepeyinti yomatshini wokutshiza ongenamoya woxinzelelo oluphezulu yi-70 ~ 150 μ m.20 ~ 50 kumatshini wokutshiza umoya μ m.Umgangatho wefilimu yepeyinti ubi kakhulu kunomoya wokutshiza, ongafanelekanga ukugubungela umhlobiso womgca omncinci.Uluhlu kunye nemveliso yokutshiza ayikwazi ukulungiswa ngexesha lokusebenza, kwaye umbhobho kufuneka utshintshwe ukuze ufezekise injongo yokulungelelanisa.

Ixesha lokuposa: Dec-02-2022